FRP grating, a lightweight, high-strength material with many merits, is widely used in various fields like sewage treatment, chemical, and more, for its excellent properties and easy processing.

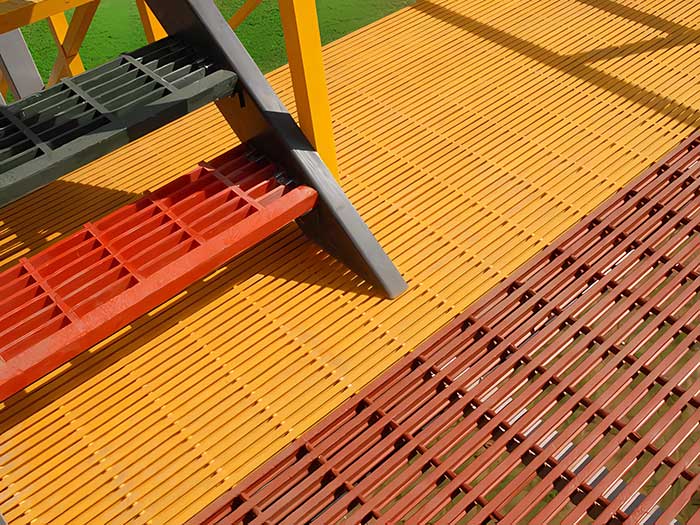

Fiberglass reinforced plastic grating, also known as FRP grating or glass fiber reinforced plastic grating, is a type of plate-shaped material with many voids, composed of glass fibers as reinforcement material and unsaturated polyester resin as the matrix material, through a special processing process. It has excellent characteristics such as lightweight, high strength, corrosion resistance, flame retardancy, and non-slip properties, making it widely used in multiple fields.

1. Corrosion Resistance: Fiberglass reinforced plastic grating has excellent corrosion resistance to acids, alkalis, organic solvents, and salts, giving it unparalleled advantages in the field of corrosion resistance.

2. Lightweight and High Strength: Due to its structural characteristics, fiberglass reinforced plastic grating is lightweight and high strength, making it easy to cut and install.

3. Flame Retardant and Insulating: Fiberglass reinforced plastic grating also has good flame retardant performance and insulation, giving it certain advantages in safe use.

4. High Temperature Resistance: Some fiberglass reinforced plastic grating products also have the characteristics of high temperature resistance, expanding its application range.

5. Aesthetic and Durable: Fiberglass reinforced plastic grating comes in various colors and styles, not only practical but also aesthetically pleasing, with a long service life and low maintenance requirements.

6. Wide Application Range: Due to its excellent performance characteristics, fiberglass reinforced plastic grating is widely used in industries such as petroleum, chemical, electronics, power generation, papermaking, printing and dyeing, electroplating, marine exploration, sewage treatment, etc., for work platforms, equipment platforms, drilling platforms, walkways, etc., and is also suitable for civilian building facilities.

7. Easy Processing and Installation: Fiberglass reinforced plastic grating is easy to cut and install, and can be customized according to actual needs to meet the requirements of different occasions.

1. Sewage Treatment: In places such as sewage treatment plants, sewage purification plants, and water treatment workshops, fiberglass reinforced plastic grating is used for maintenance walkways, trench covers, large containers, cleaners, trash racks, flow troughs, bio-water treatment pool hangers, ventilation windows, stairs, and cooling tower operation platform surfaces.

2. Chemical Industry: In chemical plants, chemical operation platforms, and acid-alkali plants, fiberglass reinforced plastic grating is used for trench covers, double-layer floors, walkways, operation platforms, tank top platforms, etc.

3. Construction Industry: As a new type of building material, fiberglass reinforced plastic grating is also widely used in the construction field, including but not limited to cover plates for industrial platforms and walkways.

4. Transportation Field: In highway construction, fiberglass reinforced plastic grating is used as guardrails and median strips on both sides of highways, effectively ensuring the safety and smoothness of highway traffic due to its lightweight, high strength, and impact resistance.

5. Power Industry: In power engineering construction and power sites, fiberglass reinforced plastic grating is also used, such as sewage treatment plant covers, trench covers, platform grids, etc.

6. Petroleum and Marine Exploration: In industries such as petroleum, chemical, electronics, power generation, papermaking, printing and dyeing, electroplating, and marine exploration, fiberglass reinforced plastic grating is an ideal product for work platforms, equipment platforms, drilling platforms, walkways, etc., in corrosive environments.

7. Agricultural Industry: Fiberglass reinforced plastic grating is also widely used as flooring for farmhouses, its concave surface and corrosion resistance make it ideal for high humidity or chemical contact areas.

8. Environmental Protection Field: Due to its corrosion resistance, heat resistance, insulation, and fire resistance, fiberglass reinforced plastic grating is hailed as the "green material of the 21st century" and is widely used in the field of environmental protection.

9. Municipal Engineering, Communities, Ports, Airports, Warehouses, and other fields.

If you want to customize fiberglass products or solve your company's storage, anti-corrosion and other industry problems, Shengte Technology is your first choice.

Tel: 86 13831860303

Email: 13831860303@126.com

Address: 598 Fuyang East Road, Jizhou District, Hengshui City, Hebei Province, China